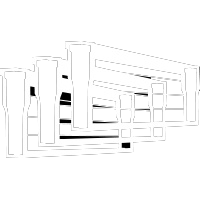

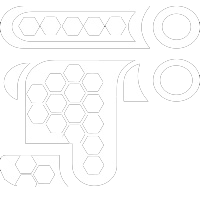

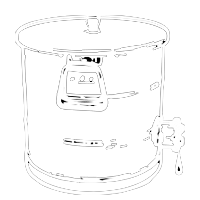

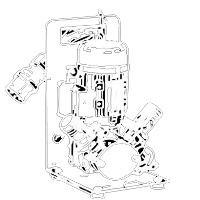

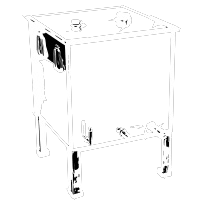

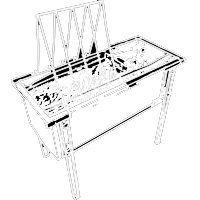

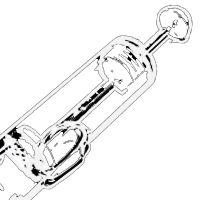

decrystallization machine, 70 L (100 kg), 400V

Honey creaming and decristalization machine, 70l (400V)

These devices are designed to carry out the honey creaming

process.

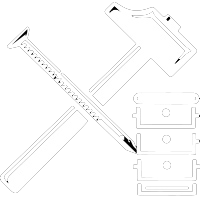

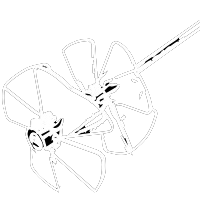

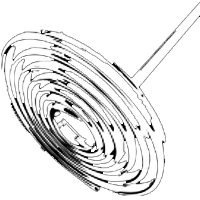

The right design of the mixing blade made of acid-resistant stainless steel

allows for the exact creaming of honey.

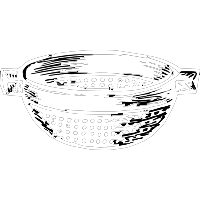

The process of creaming should take place in repetitive cycles "work - rest"

Stirrer operation - 15 min

Agitator stop 1 h.

Correctly creamy honey has a texture similar to butter.

It is possible to make devices according to individual orders.

Creaming honey

Fresh honey is thick and transparent. After some time it undergoes natural

crystallization. The proper temperature of crystallization is 16-18oC. At higher

temperatures, the crystallization process is slower and the crystals reach a

larger size.

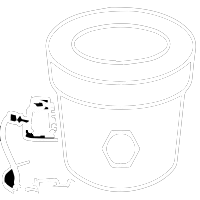

Heating honey to a temperature of 40 ° C, and maintaining it

for several days, causes honey to pass from the crystallized state to the liquid.

The creaming machine has a special mechanical stirrer that allows you to carry

out the recrystallization process, after which honey will achieve an ideal "spread"

consistency, similar to chocolate creams for children. This process involves

cyclic aeration and intensive mixing of honey for several days until the right

consistency is achieved. Aeration occurs during mixing.

Mixing is carried out several times a day for a period of

about 10-15 minutes. You can, for example, add honey crystallized to the patula

at the beginning. "Creaming" is aimed at the production of many small nuclei of

crystallization and preventing the growth of already existing honey crystals. It

is a mechanical "grinding of honey" crystals. This honey stored at a constant

temperature retains this consistency for many months.

Reviews

There are yet no reviews for this product.

Please log in to write a review. Log in